The Evolution of American Manufacturing: Visualizing the Shift from Global Dominance to Service Economy

A comprehensive analysis of America's industrial transformation and its economic implications

The Golden Age of American Manufacturing (1940s-1970s)

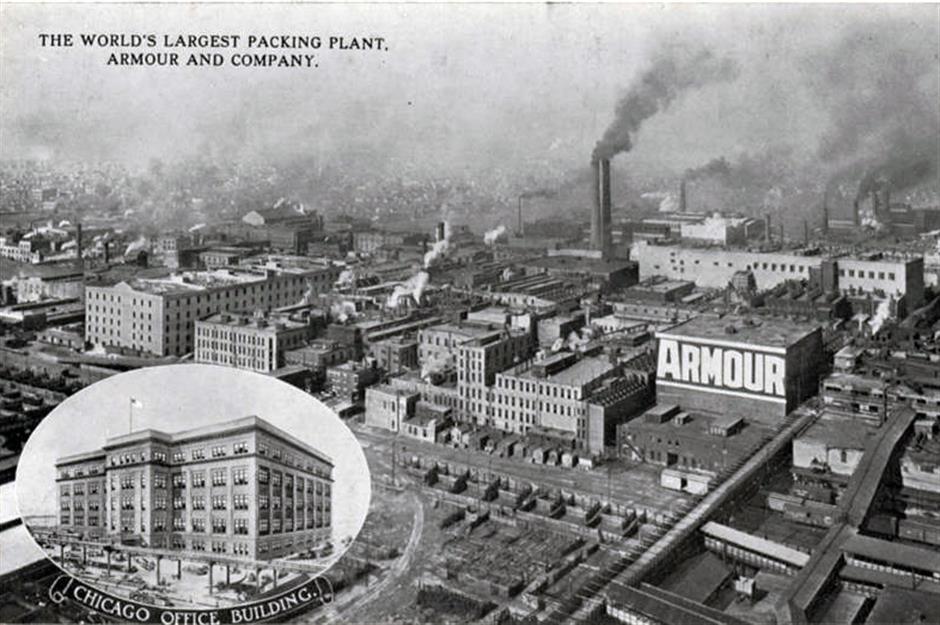

The period following World War II marked an unprecedented era of industrial growth that positioned the United States as the world's manufacturing superpower. While much of the industrial world lay in ruins after the war, America's intact manufacturing infrastructure allowed it to dominate global production for decades.

Key Factors Behind America's Manufacturing Supremacy

- Intact Infrastructure: While European and Japanese industrial facilities were devastated by the war, American factories remained operational and quickly pivoted from wartime to consumer production.

- Innovation Ecosystem: America's robust research and development environment fostered technological leadership across multiple industries, from automobiles to electronics.

- Labor Force Development: A strong union movement combined with manufacturing growth created unprecedented middle-class prosperity and a skilled workforce.

Geographic Distribution of Manufacturing

graph TD

US["United States Manufacturing Hubs

(1940s-1970s)"]

US --> Midwest["Midwest

Industrial Heartland"]

US --> Northeast["Northeast

Manufacturing Belt"]

US --> West["West Coast

Emerging Centers"]

US --> South["Southern

Manufacturing Growth"]

Midwest --> Detroit["Detroit, MI

Automobiles"]

Midwest --> Cleveland["Cleveland, OH

Steel Production"]

Midwest --> Chicago["Chicago, IL

Diverse Manufacturing"]

Northeast --> Pittsburgh["Pittsburgh, PA

Steel Industry"]

Northeast --> NY["New York Area

Diverse Industries"]

Northeast --> NE["New England

Textiles & Electronics"]

West --> LA["Los Angeles, CA

Aircraft & Defense"]

West --> SF["San Francisco, CA

Shipbuilding & Electronics"]

West --> Seattle["Seattle, WA

Aerospace"]

South --> TX["Texas

Oil & Petrochemicals"]

South --> NC["North Carolina

Textiles & Furniture"]

South --> TN["Tennessee

Emerging Manufacturing"]

classDef primary fill:#FF8000,stroke:#CC6600,color:white;

classDef secondary fill:#FFB366,stroke:#CC6600,color:#333;

classDef tertiary fill:#FFE6CC,stroke:#CC6600,color:#333;

class US primary;

class Midwest,Northeast,West,South secondary;

class Detroit,Pittsburgh,LA,TX tertiary;

class Cleveland,Chicago,NY,NE,SF,Seattle,NC,TN tertiary;

During this golden age, manufacturing became deeply intertwined with American identity and provided the foundation for middle-class prosperity. Workers could support families on a single income, purchase homes, and access education for their children. The start a business environment thrived as manufacturing supply chains created opportunities for entrepreneurs in related industries.

The Decline Trajectory: Charting Manufacturing's Structural Transformation

Beginning in the 1970s, American manufacturing entered what would become a 45-year structural decline as the United States transitioned toward a more service-oriented economy. This shift fundamentally altered the American economic landscape and changed the nation's position in the global production system.

Critical Inflection Points in Manufacturing Decline

Several key factors accelerated this manufacturing transformation:

- Global Competition Emergence: Initially from Japan and Germany, later from China and other emerging economies, overseas manufacturers with lower labor costs began challenging American industrial dominance.

- Automation and Technology: Advances in robotics and production systems reduced the need for large manufacturing workforces, even as output remained substantial in certain sectors.

- Policy Shifts: Trade agreements like NAFTA facilitated the relocation of manufacturing operations to countries with lower production costs, while domestic policy often failed to prioritize industrial retention.

Regional Economic Impacts

graph TB

subgraph "Manufacturing Job Loss Impacts"

Economy["Economic Impacts"]

Social["Social Impacts"]

Community["Community Impacts"]

end

Economy --> Unemployment["Increased

Unemployment"]

Economy --> WageLoss["Wage

Depression"]

Economy --> TaxBase["Eroded Tax

Base"]

Social --> MiddleClass["Middle Class

Contraction"]

Social --> Poverty["Increased

Poverty Rates"]

Social --> Inequality["Growing

Inequality"]

Community --> Population["Population

Decline"]

Community --> Infrastructure["Infrastructure

Deterioration"]

Community --> Services["Reduced Public

Services"]

classDef orange fill:#FF8000,stroke:#CC6600,color:white;

classDef orangeLight fill:#FFB366,stroke:#CC6600,color:#333;

classDef orangeLighter fill:#FFE6CC,stroke:#CC6600,color:#333;

class Economy,Social,Community orange;

class Unemployment,WageLoss,TaxBase,MiddleClass,Poverty,Inequality orangeLight;

class Population,Infrastructure,Services orangeLighter;

The decline of manufacturing hit certain regions particularly hard. The term "Rust Belt" emerged to describe once-thriving industrial areas across the Midwest and Northeast that experienced severe economic contraction. Cities like Detroit, Cleveland, Buffalo, and Pittsburgh saw significant population loss as manufacturing jobs disappeared. Using technology industry insights to analyze this transition reveals how manufacturing's decline reshaped not just the economy but the very fabric of American communities.

The Service Economy Transition: Understanding the New American Economic Landscape

As manufacturing declined, the American economy underwent a fundamental restructuring toward service industries. This transition created new economic hubs, changed employment patterns, and reshaped the nature of work in America.

Key Service Sectors That Absorbed the Workforce

The transition to a service-based economy was characterized by the rapid growth of several key sectors:

- Financial Services: Wall Street expansion and the proliferation of banking, insurance, and investment services created high-paying jobs concentrated in urban centers.

- Healthcare: An aging population and advances in medical technology drove substantial growth in healthcare employment, now one of the largest sectors of the American economy.

- Information Technology: The digital revolution created entirely new categories of jobs, with tech hubs emerging in regions like Silicon Valley, Seattle, and Austin.

Wage and Employment Differentials

The service economy transition created stark wage disparities. While high-skilled service jobs in finance, technology, and healthcare often paid more than traditional manufacturing positions, many service jobs in retail, food service, and hospitality paid significantly less and offered fewer benefits. This wage bifurcation contributed to growing economic inequality. Understanding these shifts requires applying the 4 Ps of marketing to how regional economies had to reposition themselves in the new economic landscape.

Regional Transformation Stories

Former manufacturing hubs had to reinvent themselves to survive. Success stories include:

- Pittsburgh, PA: Transformed from steel production center to a hub for healthcare, education, and technology, anchored by the University of Pittsburgh Medical Center and Carnegie Mellon University.

- San Francisco, CA: Evolved from a manufacturing and shipping hub to the center of the global tech industry.

- Boston, MA: Shifted from textiles and manufacturing to education, biotechnology, and finance.

The Global Context: American Manufacturing in the World Economic System

America's manufacturing transformation must be understood within the broader context of global economic evolution. As American manufacturing declined, global manufacturing output actually increased substantially, shifting to new regions and creating complex international supply chains.

Global Manufacturing Output Shifts (1950-2025)

The chart above illustrates the dramatic shift in global manufacturing output over 75 years. While the United States dominated manufacturing in the post-war era with nearly half of global production, its share has declined significantly. Meanwhile, China's emergence as a manufacturing powerhouse represents perhaps the most dramatic economic shift of the modern era.

Comparative Analysis: Manufacturing Decline Patterns

| Country | Peak Manufacturing Era | Primary Causes of Decline | Policy Response |

|---|---|---|---|

| United States | 1945-1970 | Global competition, automation, trade policies | Limited industrial policy, focus on service economy |

| United Kingdom | 1870-1920 | Earlier deindustrialization, rigid institutions | Financial services focus, privatization |

| Japan | 1970-1990 | Rising costs, competition from other Asian countries | Industrial policy, high-tech manufacturing focus |

| Germany | 1950-present | Limited decline, maintained manufacturing strength | Strong apprenticeship programs, innovation focus |

Looking forward to the global economy 2025, American manufacturing now operates in a vastly different context than during its heyday. Global supply chains have become increasingly complex, with products often designed in one country, with components manufactured across multiple nations, before final assembly elsewhere. The diagram below illustrates this complexity using a simplified smartphone production example:

flowchart LR

subgraph "Modern Global Supply Chain: Smartphone Example"

Design["Product Design

USA/Europe"]

Components["Component Manufacturing

Multiple Countries"]

Assembly["Final Assembly

China/Vietnam"]

Distribution["Global Distribution

Multinational Network"]

Design --> |Specifications| Components

subgraph "Component Sources"

Chips["Semiconductors

Taiwan, S. Korea, USA"]

Display["Display

S. Korea, Japan"]

Battery["Battery

China, Japan"]

Camera["Camera Modules

Japan, China"]

Others["Other Components

Malaysia, Thailand, Mexico"]

end

Components --> Chips

Components --> Display

Components --> Battery

Components --> Camera

Components --> Others

Chips --> Assembly

Display --> Assembly

Battery --> Assembly

Camera --> Assembly

Others --> Assembly

Assembly --> Distribution

Distribution --> Markets["Global Markets"]

end

classDef orange fill:#FF8000,stroke:#CC6600,color:white;

classDef orangeLight fill:#FFB366,stroke:#CC6600,color:#333;

classDef blue fill:#42A5F5,stroke:#1976D2,color:white;

classDef green fill:#66BB6A,stroke:#388E3C,color:white;

class Design orange;

class Components,Chips,Display,Battery,Camera,Others blue;

class Assembly,Distribution green;

class Markets orangeLight;

Modern Revitalization Efforts: The Emerging Manufacturing Renaissance

Despite decades of decline, American manufacturing has shown remarkable resilience and signs of revitalization in recent years. New approaches to production, combined with changing global conditions, have created opportunities for manufacturing renaissance in certain sectors and regions.

Key Drivers of Manufacturing Resurgence

Several key factors are contributing to manufacturing's potential revitalization:

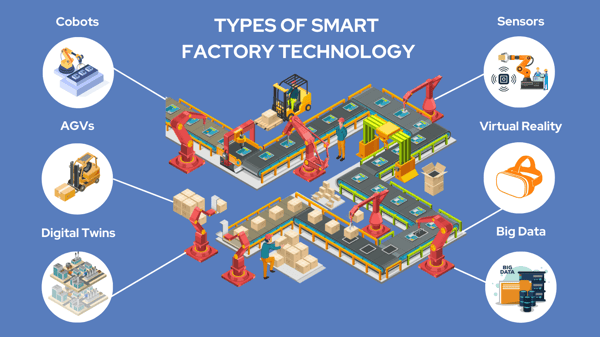

- Advanced Manufacturing Technologies: Innovations like 3D printing, digital twins, and smart factories are creating new production paradigms that can succeed in high-cost environments.

- Supply Chain Security: The COVID-19 pandemic exposed vulnerabilities in extended international supply chains, driving interest in reshoring critical production capacity.

- Strategic Industrial Policies: Recent legislation like the CHIPS Act and Inflation Reduction Act contains significant support for domestic manufacturing in strategic industries.

Case Studies of Manufacturing Revival

Electric Vehicle Production

The emergence of electric vehicle manufacturing has created new production hubs in states like Tennessee, Kentucky, and Texas. These advanced facilities combine cutting-edge automation with skilled workforce deployment.

Semiconductor Industry

With over $50 billion in government support through the CHIPS Act, semiconductor manufacturing is expanding in states like Arizona, Ohio, and New York, addressing critical technology supply chain vulnerabilities.

Additive Manufacturing Hub

Pittsburgh has leveraged its engineering expertise to become a center for additive manufacturing (3D printing), with companies like GE and startups creating an innovation ecosystem around this technology.

Medical Device Manufacturing

Minneapolis-St. Paul has maintained and grown its medical device manufacturing sector through a combination of innovation, specialized workforce development, and industry clustering.

PageOn.ai's visualization tools can help industries identify and analyze manufacturing revival trends by creating clear visual narratives of transformation processes. By mapping the ecosystem connections through the intelligent agents industry ecosystem lens, we can better understand how technology integration drives modern manufacturing evolution.

The Future Landscape: Visualizing American Manufacturing's Next Chapter

As we look toward the future, American manufacturing faces both challenges and opportunities. The sector is unlikely to return to its mid-20th century form, but it may evolve into something equally powerful though fundamentally different in character and impact.

Emerging Technologies Reshaping Production Possibilities

%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#FF8000', 'primaryTextColor': '#fff', 'primaryBorderColor': '#CC6600', 'lineColor': '#A0A0A0', 'secondaryColor': '#FFB366', 'tertiaryColor': '#FFE6CC' }}}%%

mindmap

root((Future

Manufacturing

Technologies))

::icon(fa fa-industry)

(AI & Automation)

::icon(fa fa-robot)

(Collaborative Robots)

(Predictive Maintenance)

(Autonomous Production)

(Computer Vision QC)

(Additive Manufacturing)

::icon(fa fa-cubes)

(Multi-Material 3D Printing)

(Mass Customization)

(On-Demand Production)

(Advanced Materials)

::icon(fa fa-atom)

(Nanomaterials)

(Composites)

(Programmable Materials)

(Distributed Production)

::icon(fa fa-network-wired)

(Microfactories)

(Local Supply Chains)

(Urban Manufacturing)

(Sustainable Production)

::icon(fa fa-leaf)

(Circular Economy)

(Zero-Waste Processes)

(Renewable Energy Integration)

The future of American manufacturing will be shaped by several emerging technologies that fundamentally change how products are designed, produced, and distributed:

- AI and Automation Integration: Beyond simple robotics, AI will enable adaptive production systems that can more fluidly respond to changes in design, materials, and order specifications.

- 3D Printing and Additive Manufacturing: As these technologies mature, they enable production closer to the point of use, with greater customization and less material waste.

- Green Manufacturing: Sustainability imperatives will drive the development of circular production systems that minimize material usage, energy consumption, and environmental impacts.

Future Scenarios for American Manufacturing

Three potential scenarios emerge for American manufacturing by 2030:

- High-Tech Renaissance: Significant growth in high-value manufacturing sectors like advanced computing, biotechnology, aerospace, and clean energy, with strong productivity but modest employment gains.

- Distributed Manufacturing Network: More geographically dispersed production using technologies like 3D printing, creating resilient local supply chains but with potentially lower total output value.

- Continued Decline: Further erosion of manufacturing capacity if policy, investment, and innovation fail to overcome competitive challenges.

The most likely outcome is a hybrid future that combines elements of the first two scenarios, with specialized production hubs for advanced industries alongside more distributed manufacturing networks for consumer goods and components.

Workforce Development Implications

The future of American manufacturing will require a different workforce than in the past. Key skills will include:

- Human-Machine Collaboration: Working alongside advanced robotic systems and AI assistants

- Digital Literacy: Understanding digital production systems, simulation tools, and data analysis

- Cross-Disciplinary Knowledge: Combining mechanical skills with programming, materials science, and design thinking

- Adaptability: Continuous learning to keep pace with rapidly evolving production technologies

Transform Your Economic Insights with PageOn.ai

Create powerful visualizations to understand complex economic transitions and manufacturing trends. PageOn.ai helps you translate complex data into clear, compelling visual narratives.

Start Creating Visual Economic Insights TodayConclusion: The Continuing Evolution of American Manufacturing

The story of American manufacturing is one of continuous transformation. From its post-war golden age to its structural decline and now potential reinvention, manufacturing has both shaped and been shaped by broader economic and technological forces.

While manufacturing may never again dominate American employment as it once did, its strategic importance remains critical. Advanced manufacturing capabilities are essential for national security, innovation ecosystems, and maintaining America's position in the global economy.

The future of American manufacturing will be defined not by a return to the past but by embracing new production paradigms that leverage technological advantages, sustainability imperatives, and America's continuing capacity for innovation and adaptation. Through the effective visualization of these complex transitions using tools like PageOn.ai, we can better understand the challenges and opportunities that lie ahead for this crucial sector of the American economy.

You Might Also Like

How to Design Science Lesson Plans That Captivate Students

Create science lesson plans that captivate students with hands-on activities, clear objectives, and real-world applications to foster curiosity and critical thinking.

How to Write a Scientific Review Article Step by Step

Learn how to write a review article in science step by step. Define research questions, synthesize findings, and structure your article for clarity and impact.

How to Write a Self-Performance Review with Practical Examples

Learn how to write a self-performance review with examples and tips. Use an employee performance review work self evaluation sample essay to guide your process.

How to Write a Spec Sheet Like a Pro? [+Templates]

Learn how to create a professional spec sheet with key components, step-by-step guidance, and free templates to ensure clarity and accuracy.